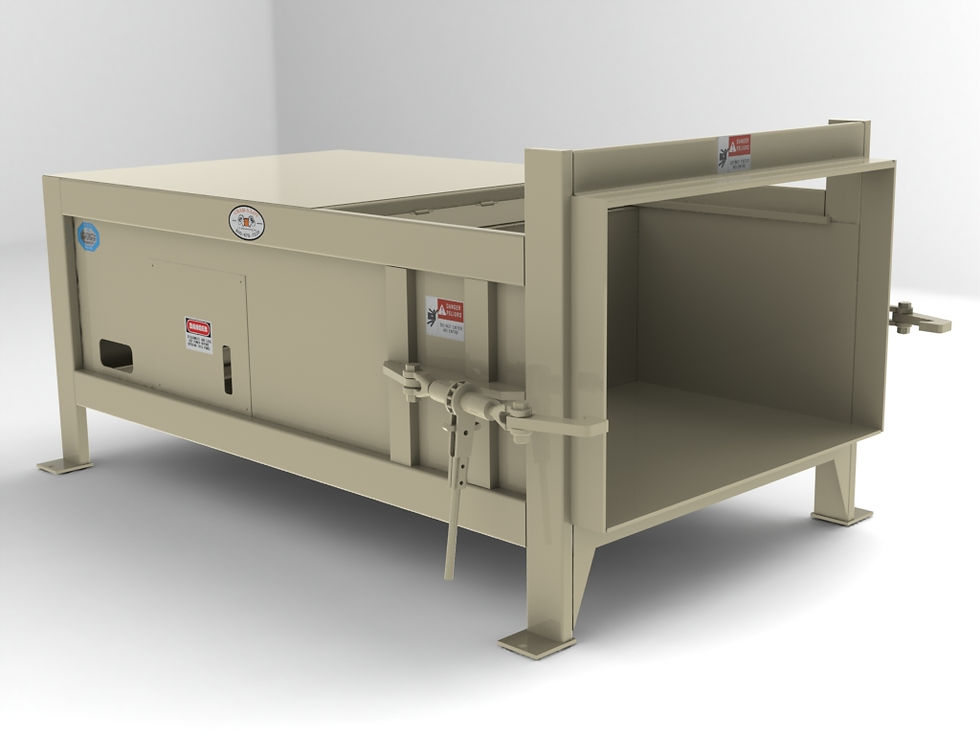

Stationary Compactors

Contact us for Ordering 501.425.1567

We offer Stationary Compactors in various sizes from 2 yard to 12 yard for your waste disposal needs. Each unit is designed to safely, quietly and efficiently compact your waste.

We offer Stationary Compactors in various sizes from our 2-4 yard Commercial Compactors to the Heavy Industrial 5-15 Yard Compactors. Each unit is designed to safely, quietly and efficiently compact your waste and can be custom designed and factory installed to suit your special applications.

Standard features include:

-

ANSI Z245.2 Compliant - All compactors meet or exceed ANSI Z245.2 safety standards.

-

UL/CUL Listed Control Panels

-

UHMW Ram Guides - Adjustable to assure straight tracking and readily replaceable, should the need arise

-

Oil Sight Gauge - Oil level at a glance

-

Heavy Duty Controls - NEMA 4 rated pushbutton controls with key-lockable start switch

-

Automatic Single Cycle Operation

-

Commercial Size 2-4 Yard Compactors

Commercial size compactors are designed for moderate duty service. They are perfect for retail stores, light industrial plants, grocery stores, hospitals and many more similar applications.

The 4-yard compactor is designed for heavy commercial, industrial and mini-transfer stations and is engineered to handle above average quantities of refuse when a transfer station is not applicable.

Commercial size compactors offer integral power units to the compactor chassis for security, yet accessible for ease of maintenance and repairs.

Large Industrial 5-15 Yard Compactors

Large Industrial compactors are designed for heavy industrial duty service. They are perfect for manufacturing facilities, heavy industrial plants, transfer stations and similar applications.

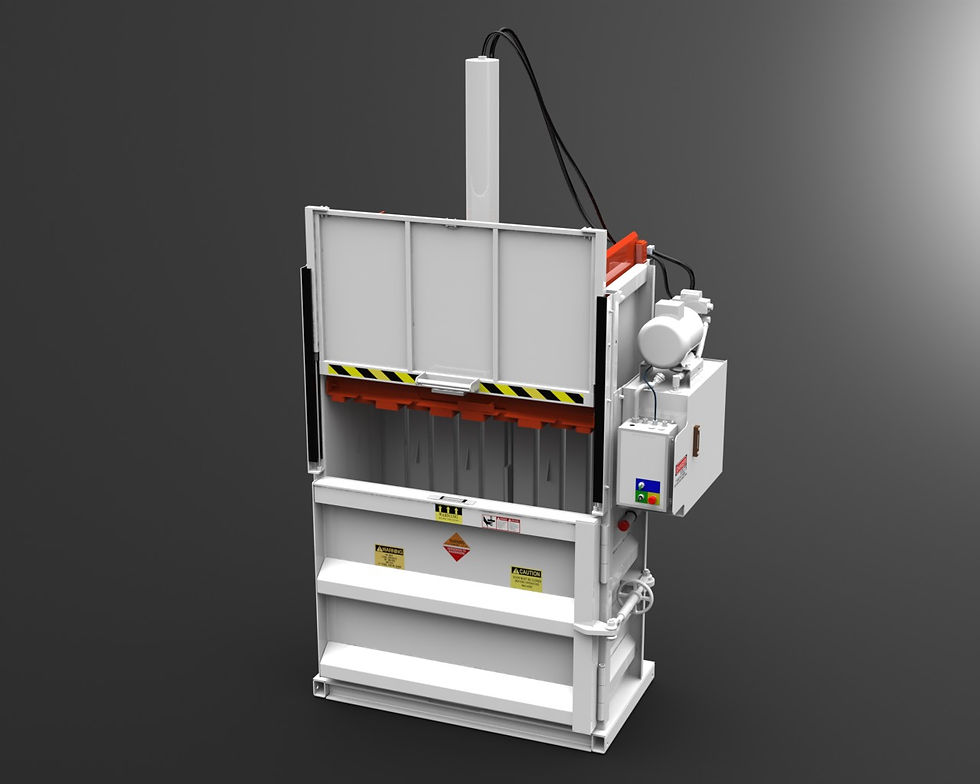

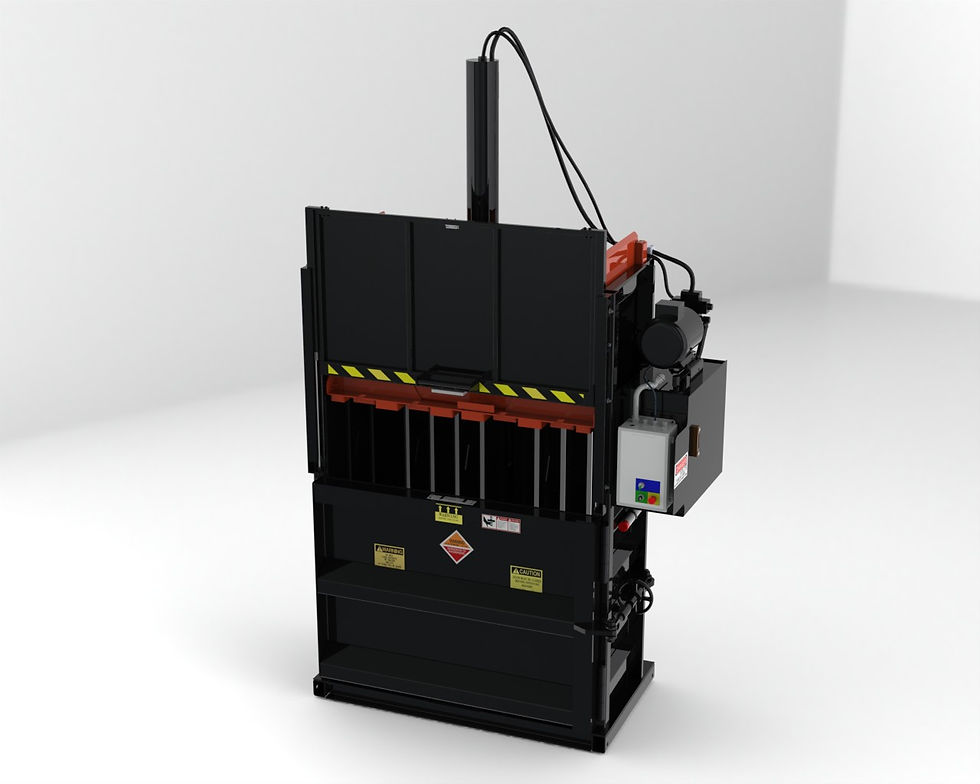

The revolutionary design of the VB Baler offers safety and simplicity like no other on the market. A gas spring loading gate solves the age-old chain, sprocket and pulley reliability problem.

J.V. Manufacturing, Inc. offers a complete line of vertical balers to fit your recycling needs. Balers to recycle small volumes of aluminum or plastic on an ongoing basis or balers to recycle cardboard the size of refrigerator boxes. All designed to quietly, efficiently and safely compact your recyclable materials.

The VB series baler was introduced in 2002 with the most sweeping changes in baler technology in decades. The VB Baler was designed for improved safety and ease of maintenance.

Specific features include:

-

Loading Door - Chain and sprocket problems have been replaced with a patent pending system that utilizes gas springs to smoothly open the loading door after each compaction stroke and significantly reduce the opportunity for hand injury.

-

Safety Interlock - The entire operational circuit of the baler is controlled by a patent pending design that utilizes an

-

Electro-Magnet to hold the loading door securely in place until the baler has completed the compaction cycle and is in position to re-load.

-

Control Panel - Innovative design and layout of the control panel has allowed switches, operators and interlocks to be reduced by 50%, reducing maintenance costs.

-

Side Mounted Power Unit – The power unit has been redesigned for simplicity and reliability, and also relocated to the side of the baler chassis for safer and easier maintenance. Brand name components are used to ensure long term reliability. A direct drive vane pump is mounted directly to the motor flange, thereby eliminating the motor coupler and providing quieter and more reliable operation. The directional valve is mounted directly to the pump body, eliminating up to 50% of the hoses and potential leak points that exist on comparable models. All CRAM-A-LOT® power units are manufactured and assembled “in house” using brand name components.

-

Patented Bale Eject System - Unique design protects against bale eject system failure

-

ANSI Z245.5 Compliant